RESEARCH PROGRAM

Title: Kinematic simulation of micro grinding processes

Name: Nicolas Altherr

E-Mail: Nicolas.altherr@mv.uni-kl.de

Phone: +49 631 205-5283

Project description:

Starting situation

Due to increasing demand on components and structures with a range of microns there is a rising need for fast and flexible micro machining processes able to produce them. One of those processes is grinding with micro grinding pencil tools. It is used, for instance, to manufacture optical surfaces. However, in micro grinding only few, i.e. the most protruding grits, contribute to surface generation due to tool diameters below 1 mm. This leads to a higher influence of single grits on the resulting surface topographies. Focusing on peripheral grinding, those grits are located at the shell surface of the cylindrical tool geometry. Therefore, they do not intervene with the workpiece continuously but periodically.

Approach

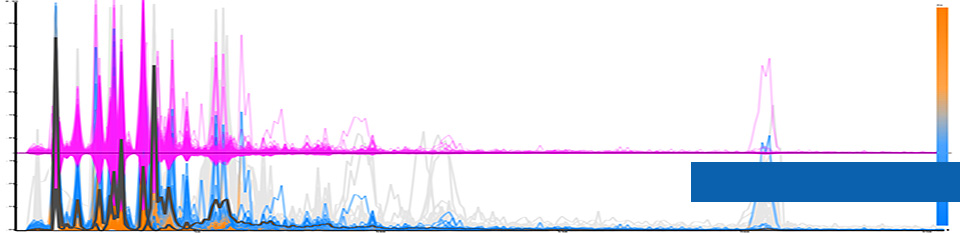

A detailed understanding of the micro grinding process is necessary in order to improve the resulting surface topography. Therefore, both, experimental and simulative investigations of peripheral grinding are performed within this project. Experiments are used to examine differences between workpiece surface and ideal surface. Reasons of those differences are identified by kinematic simulations. This type of simulations offers the possibility of focusing on specific kinematic effects and their influence on the resulting tool topography ignoring disturbances.

Expected Results

Main goal of the project is to understand the relationship of cause and effect of surface generation in micro grinding processes. In doing so, influences of single grits, tool wear, and process-machine-interactions on the workpiece topography are considered. As process-machine-interactions, basically run-out errors and spindle vibrations are taken into account. The results are used to improve the produced surface quality.