RESEARCH PROGRAM

Title: A Data-Driven Approach to Analyzing Machining Energies of Various Materials

Name: Maxwell Micali, PhD

(former student)

Project description:

Starting situation

The current state of knowledge says that a material’s hardness is the most influential factor in how much energy that material takes to machine, otherwise known as that material’s specific cutting energy. While this claim has been accepted, there has not been a thorough analysis of material hardness in comparison with other material properties to determine which material properties may in fact be the most dominant for specific cutting energy, hardness or others.

Approach

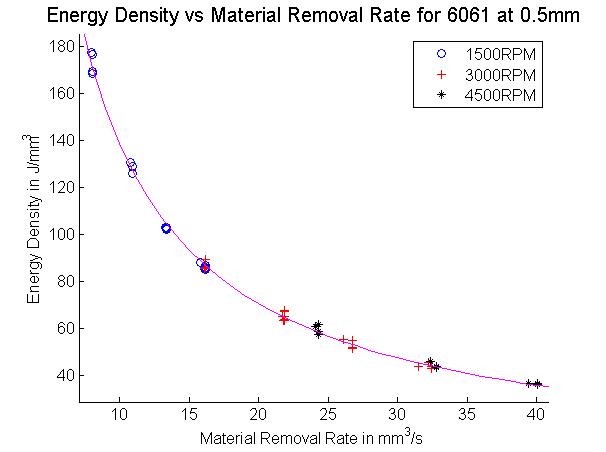

This project takes an experimental approach to analyzing the effects of different material properties on specific cutting energy. This is conducted on an MTConnect enabled 3 axis milling machine, and consists of machining the same toolpath. with a variety of features, on a set of samples from different materials with known (reported from the manufacturer or measured) material properties. By measuring the instantaneous energy consumption from a power monitor and corresponding that data to features of the toolpath, each toolpath constitutes a number of individual experiments on that material sample. Regressions are then conducted to determine the influence of each of the material properties in question.

Expected Results

The expected outcome of this work will be material independent energy prediction model for a milling machine tool.