RESEARCH PROGRAM

Title: Surface Integrity & Process Optimization during Finishing Operations

Name: Jayanti Das, PhD

(former student)

Project description:

The aim of this research is to find a correlation between different roughness parameters with surface functionality under different finishing operations. Depending on the type of finishing operations, the process optimization requires to minimize the energy consumption and to increase the process efficiency. In this research, belt grinding, vibratory tumbling, and hand held grinder have been used for finishing operations.

Starting situation

Grinding processes are often used for final finishing operations because of it’s ability to satisfy the requirement for surface roughness and tolerance. The reliability of the machined surface is critically dependent upon the quality of the surface. The quality of the surface can be broadly divided into two parts: surface integrity and surface topography. Surface integrity is associated with mechanical and metallurgical properties of the surfaces (hardness, friction, microstructure deformation) and surface topography refers to geometry of machined surface, which is usually characterized by surface roughness.

Approach

1. Find correlation between different roughness parameters with surface functionality during different manual finishing operations.

2. Choose the most suitable finishing operations and optimize the process parameters.

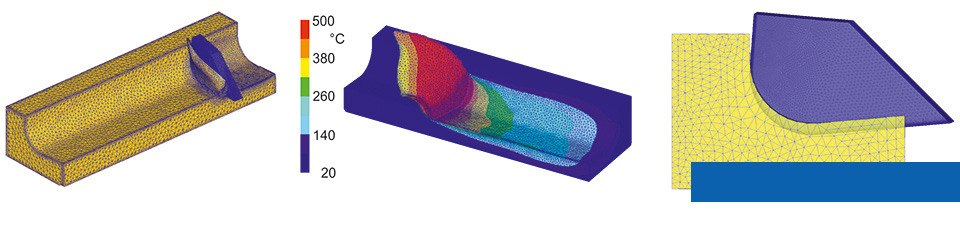

3. Generate the process model to prove the proof of concept.

4. Application study: Effect of microbial attachment on surfaces in food industry.

5. Overall sustainability aspect analysis.

Expected Results

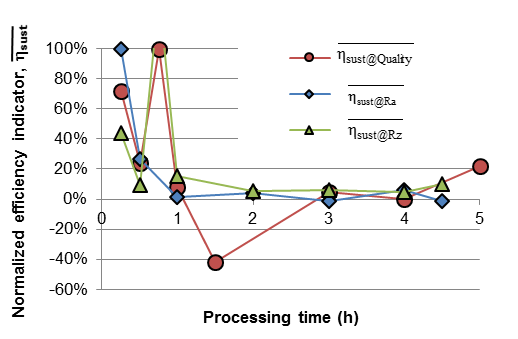

Fig: Normalized efficiency indicators over processing time in Vibratory Tumbling

Fig Ref: Linke, B. Das, J.: Procedia CIRP 14, 2014, 564