RESEARCH PROGRAM

Title: Experimental investigations and simulation of micro grinding process

Name: Prof. Dr. Dinesh Setti

(former student)

Project description:

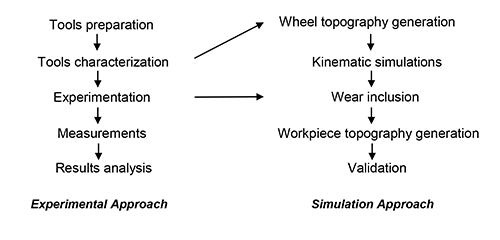

For a conventional grinding wheel, information about wheel structure (open or dense) is readily available, and the wheel selection can be made accordingly for a specific condition. However, in micro grinding, there is no such a universal system as the wheels/pencil tools were developing indigenously. It makes difficulty in selecting the suitable micro grinding wheel/pencil tool for a specific requirement. Moreover, rapid wear of the micro grinding tool significantly effects the dimensional accuracy as well as the surface topography of component. In this situation, there is a need to study and predict the effect of different wheel topographies on the micro grinding process.

Approach

Expected Results

- Selection of proper micro grinding tool and cutting conditions

- Influence of variables on response

- Information about wheel wear modes and mechanisms with different tool topographies in micro grinding

- Prediction of channel surface roughness and dimensional accuracy variation with wheel wear